1.Product Brief

Magnetic separator -ZDZG® uses dynamic magnetic system design, which has good separating effect.It has the following advantages: large magnetic field strength, large handling capacity, low maintenance rate, simple structure, easy operation, adjustable magnetic field intensity and large output.

2.Classification

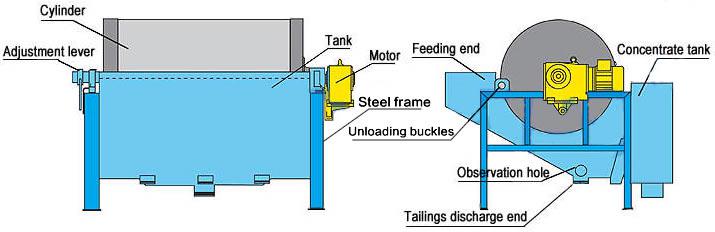

The magnetic separator can be divided into dry magnetic separator and wet magnetic separator according to the medium of the sorting process.

Dry magnetic separator is commonly used iron ore equipment and manganese ore equipment. The dry magnetic separator is a kind of magnetic separation machine for the separation of dry magnetic minerals. The dry magnetic separator requires the minerals to being stored be dry, and the particles can move freely and form an independent free state, otherwise it will affect the magnetic separation effect and even cause the non separation results.

Wet magnetic separator is one of the most widely used and versatile machines in the industry. It is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with particle size less than 3mm, and also for iron removal of coal, non-metallic ore, building materials and other materials.

3.Working Principle

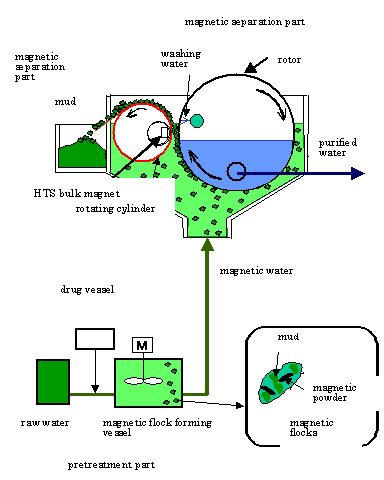

After the pulp flows into the tank through the ore feed tank, the ore particles enter the ore feed area of the tank in a loose state under the action of the jet stream. Under the action of magnetic field, the magnetic ore particles gather to form 'magnetic ball' or 'magnetic chain'. The 'magnetic ball' or 'magnetic chain' moves towards the magnetic end in the ore pulp under the action of magnetic force and is adsorbed on the cylinder. Because the magnetic ends are arranged alternately along the rotation direction of the cylinder and are fixed during operation. The 'magnetic ball' or 'magnetic chain' will produce magnetic agitation phenomenon due to the alternation of the magnetic ends when 'magnetic ball' or 'magnetic chain' rotating with the cylinder, the gangue and other non-magnetic minerals mixed in the 'magnetic ball' or 'magnetic chain' will fall off during turnover, and the 'magnetic ball' or 'magnetic chain' absorbed on the surface of the cylinder are the ore concentrate.

The ore concentrate is transferred to the place where the magnetic force is weak, and is discharged into the ore concentrate tank under the action of flushing water from the ore discharge pipe. If it is a full magnetic roller, the ore discharge is carried out with a brush roller. The non-magnetic or weak magnetic minerals are left in the slurry and then discharged out of the tank with the slurry, namely tailings.

4.Product Advantages

4.1 Advanced Structure, Large Processing Capacity

Combined with advanced technology at home and abroad, the magnetic separator has advanced structure. With the open magnetic system, the material is not wrapped up and there is no clogging, so the processing capacity is large. The processing capacity of a single primary separator can reach more than 50 tons, and multiple machines can be used in parallel, which can double the output.

4.2 Convenient Operation, Wide Application

The magnetic separator has simple structure and it is easy to operate. This series of magnetic separators are suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with a particle size of 0.1-3mm, and also for iron removal of coal, non-metallic ore, building materials and other materials. Flexible application, one machine with multiple functions.

5.Magnetic Separator Manufacturers-ZDZG®

Henan Zhongde Mining Machinery Co., Ltd is a joint-stock mining machinery manufacturing enterprise integrated in scientific research, production and marketing. With an area of 50 thousand ㎡ which includes 15,000 ㎡ of standard heavy duty industrial workshop, Zhongde produces and exports sandstone crushing equipment, powder grinding equipment, mineral processing equipment, dryer machine equipment and building materials equipment, etc. We can design the machines according to your special requirements, and we provide one-stop turnkey solutions.

If you need our magnetic separator, please contact us. Choose Our Machine, Choose Your Comfort.

NOTE: please feel free to fill out the form below in detail and you can also send a message to us(sino@zdzg.com), we will send you latest price within 24 hours.Besides, you can click Chat Online on the right hand side to get quotation online