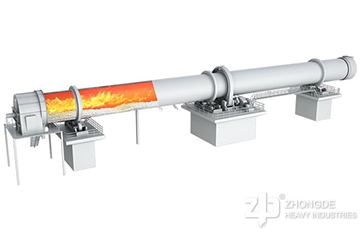

Lime kiln is also called lime rotary kiln. In the past, lime kiln production without advanced dust removal sealing technology, which often cause environmental pollution, not only the quality of finished products is not high, but also bring some trouble to the environment. The new environment-friendly lime kiln produced by zhongde heavy industry adopts advanced sealing and dust removal technology, and aims at environmental protection and quality together. Compared with traditional rotary kiln products, the environment-friendly lime kiln-ZDZG® has the advantages of higher, larger and more environmental protection.

1. Working Principle:In the processing of working, crushed limestone is fed to the pre-heating device and gets heat exchange with smoke. 30% Calcium carbonate begins to dissociate in kiln. Then preheated lime gets into the calcination. Lime goes slowly through the pre-heating zone, calcination zone and cooler, in which it is calcinated into CaO and CO2. Finished lime is cooled below 100℃, the exhaust gas is collected in dust collector.

2. Product Advantages

2.1 Higher Quality Finished Products

The length of the new environmental lime kiln is shorter. The shortening of the length not only reduces the heat loss from the surface of the kiln to the surrounding area, but also reduces the floor area of the equipment, which is more energy-saving. At the same time, the materials roll forward evenly in the lime kiln so that the heat is even, the product quality is stable. And the high activity lime can be calcined. Under the same conditions, the lime activity produced by the ZDZG®lime kiln is 30ml higher than that of the shaft kiln, its activity can reach 400ml, and the quality of the finished product is more stable.

2.2 Greater Productivity

The production capacity of ZDZG®-lime kiln is 180-1000 T/D, and appropriate equipment models and specifications can also be customized according to the actual production scale of users. Various lime kiln production lines are also widely used in large and medium-sized building materials enterprises, and they are in good operation. There is a successful project information:

Project: 500T/D Rotary Kiln Used In Active Lime Production In Philippines

Capacity: 600t/D

Material: limestone

The purchasing equipment of our customer: rotary kiln

Customer's feedback: We are zhongde's old customers, In the past two years, this plant has brought me great profit! Many friends asked me where I bought the equipment after their visit to my working site.

2.3 More Energy Saving and Environmental Protection

A vertical pre-heater is installed at the end of the lime kiln to directly transmit the waste heat of the flue gas at the end of the kiln to the limestone. The temperature of the flue gas can be reduced to below 280 ℃, which effectively recovers the heat taken by the exhaust gas discharge and reduces the load for the subsequent dedusting. The calcined tail gas is dedusted by pulse bag filter, which meets the national emission standard and implements the environmental protection to every link of production.

3. Model Specification of Lime Kiln

The following is common lime kiln model specifications for your reference:

| Design capacity (t/d) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 | |

| Product | Active lime Calcined dolomite | Active lime Calcined dolomite | Active lime Calcined dolomite | Active lime Calcined dolomite | Active lime Calcined dolomite | Active lime Calcined dolomite | Active lime Calcined dolomite | Active lime Calcined dolomite | Active lime Calcined dolomite | Active lime Calcined dolomite | Active lime Calcined dolomite | |

| Preheater | round vertical pre- heater or polygonal vertical pre- heater | round vertical pre- heater or polygonal vertical pre- heater | round vertical pre- heater or polygonal vertical pre- heater | round vertical pre- heater or polygonal vertical pre- heater | round vertical pre- heater or polygonal vertical pre-heater | round vertical pre- heater or polygonal vertical pre- heater | round vertical pre- heater or polygonal vertical pre- heater | round vertical pre- heater or polygonal vertical pre- heater | Vertical Polygon preheater | Vertical Polygon preheater | Vertical Polygon preheater | |

| Rotary kiln | Specification (m) | Φ2.5 × 40 | Φ2.8 × 42 | Φ3 × 46 | Φ3.2 × 50 | Φ3.5 × 54 | Φ3.6 × 56 | Φ3.8 × 58 | Φ4×60 Φ4.2×50 | Φ4.3 × 58 | Φ4.3 × 64 | Φ4.8 × 68 |

| Effective volume (m³) | 142 | 190 | 235 | 292 | 390 | 430 | 505 | 575/548 | 670 | 738 | 1005 | |

| Burning temperature (°C) | 1350/ 1250 | 1350/ 1250 | 1350/ 1250 | 1350/ 1250 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | |

| Cooler | Vertical Square Cooler | Vertical Square Cooler | Vertical Square Cooler | Vertical Square Cooler | Vertical Square Cooler | Vertical Square Cooler | Vertical Square Cooler | Vertical Square Cooler | Vertical Square Cooler | Vertical Square Cooler | Vertical Square Cooler | |

| Fuel | Coal gas Coal powder | Coal gas Coal powder | Coal gas Coal powder | Coal gas Coal powder | Coal gas Coal powder | Coal gas Coal powder | Coal gas Coal powder | Coal gas Coal powder | Coal gas Coal powder | Coal gas Coal powder | Coal gas Coal powder | |

| Heat rate ( KJ/KgC3O ) | 5300/ 5000 | 5300/ 5000 | 5300/ 5000 | 5300/ 5000 | 5225 | 5225 | 5100 | 5100 | 4810 | 4810 | 4810 | |

4.Service Steps

NOTE: please feel free to fill out the form below in detail and you can also send a message to us(sino@zdzg.com), we will send you latest price within 24 hours.Besides, you can click Chat Online on the right hand side to get quotation online