Magnetic separation and foam flotation are common beneficiation equipment in the beneficiation process, mainly used for beneficiation.

1.How do magnetic separators and flotation machines work?

Magnetic separator is the key mineral separation equipment for separating magnetic minerals from non-magnetic minerals or minerals with magnetic differences. The process is based on the different components in the separated materials, which means that in the working magnetic field, different magnetic field forces and other forces received by different particles can be used to separate different materials.

Froth flotation is a method of separating minerals from impurities or one mineral from another. Stir the unpurified ore powder with water and reagents. The reagents preferentially adhere to the target ore and change its surface characteristics. Then air is introduced into the mixture, and the target mine floats up to the surface of the mixture with bubbles to form foam. After defoaming, the target mine can be obtained.

2. What kind of mineral can be processed by magnetic separator?

In order to achieve the separation of different minerals through magnetic separation, it is necessary to ensure that the force difference between different magnetic materials is obvious, especially the magnetic force difference.

Minerals in nature show different magnetic properties under the action of magnetic field due to their different atomic structures, and different minerals show larger magnetic differences. Minerals are divided into non - magnetic minerals, weak magnetic minerals and strong magnetic minerals. Among them, strong magnetic minerals are the least. There are dozens of weakly magnetic minerals, while there are many kinds of non-magnetic minerals.

The most commonly used magnetic separator is high gradient magnetic separation (HGMS), high intensity magnetic separation (HIMS) and low intensity magnetic separation (LIMS), etc.

3.What kind of mineral can be processed by flotation machine?

Flotation machine is mainly used for sorting copper, zinc, lead, nickel, gold and other non-ferrous metals, as well as non-ferrous and non-metallic.

Flotation machine classification mainly includes SF type flotation machine, BF type flotation machine, KYF type flotation machine, XCF type flotation machine.

4.Example of magnetic separator for ore treatment

Magnetic separation process of wolframite

Wolframite is a weakly magnetic mineral which can be separated by magnetic separation.

The magnetic separation process of Wolfram ore coarse concentrate: before separation, the materials are crushed to 3 mm by roller crusher, and then they are screened into three grades of 0.83 ~ 3 mm, 0.2 ~ 0.83 mm and 0 ~ 0.2 mm. Finally, Wolfram concentrate can be obtained by magnetic separation method.

5.Example of foam flotation equipment for ore treatment

Copper flotation process

Copper is the most valuable recoverable element in ore, with content of 0.77%. Copper ore contains slightly oxidized sulfide ore, and copper in ore mainly exists in copper sulfide minerals. In the copper ore, the primary copper sulfide accounted for 0.45%, accounting for 60.57% of the total copper. Secondary copper sulfide 0.27%, accounting for 36.34% of the total copper; The content of free copper oxide and total copper is relatively small.

Generally speaking, modern copper ore dressing technology includes flotation, microbial leaching, separation and beneficiation, etc.

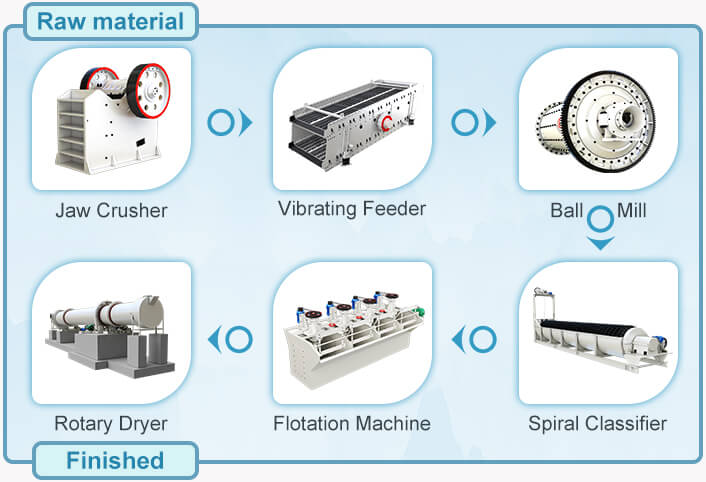

Single sulfide ore is mainly treated by flotation, the whole process includes crushing, grinding, grading and flotation. Under the proper grinding fineness and reagent system, a concentrate with a copper grade of 23.86% and a recovery of 95.24% can be obtained from the raw ore with a copper content of 0.77%.

6.Where to buy high quality mineral processing equipment?

ZhongDe Brand is a Chinese famous brand, which has been in existence for more than 35 years since its establishment. All of the products have passed the authentication of ISO 9001, CE and GOST.

Zhongde magnetic separators and flotation machines are available in a variety of models to maximize the recovery of precious metal minerals and help customers improve their economic performance.

NOTE: please feel free to fill out the form below in detail and you can also send a message to us(sino@zdzg.com), we will send you latest price within 24 hours.Besides, you can click Chat Online on the right hand side to get quotation online