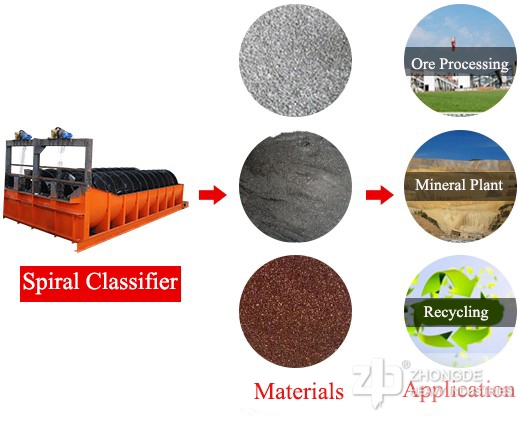

Application of Spiral Classifier

The spiral classifier is a sorting device that combines the ball mill forming a closed cycle in the beneficiation production line . The classifier is suitable for classifying ore and fine mud in the concentrator, classifying different sizes of the slurry in the metal beneficiation process, and deliming and dewatering in the washing operation, for washing, grading and removing impurities in the hydropower and construction industries, and for fine-grained and coarse-grained material separating in other operations.

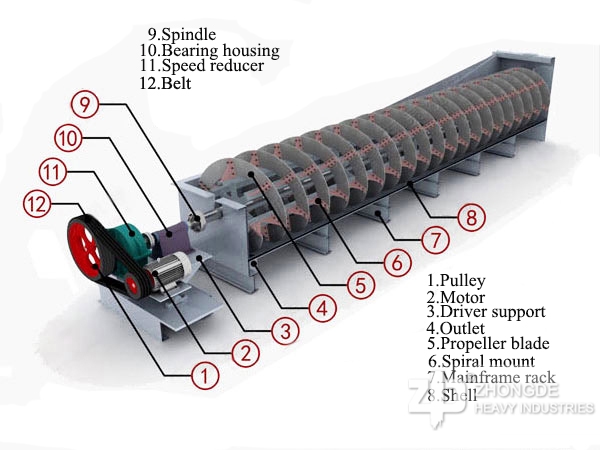

Structure of Spiral Classifier

The classifier is mainly composed of a transmission device, a spiral body, a trough body, a lifting mechanism, a lower bearing (bearing bush) and a discharge valve.

Working Principle of Spiral Classifier

When the spiral classifier is working, the fine particles and coarse ore particles are sorted by the different sedimentation speeds in the liquid by means of different solid particle sizes and different specific gravities. The ground slurry is fed into the water tank from the feed port, the machine spirally rotated, and the slurry is stirred. The coarse material is screwed into the mill feed port by the spiral piece, and the filtered fine material is discharged from the overflow pipe.

Classification of Spiral Classifier

According to the structure and the single and double helix, the spiral classifier is mainly divided into a high-grade single-screw classifier, a high-grade double-spiral classifier, a sunken single-screw classifier, and a sunken double-spiral classifier. The sunken spiral classifier is mainly used for fine-grain classification, and the high-grade spiral classifier has better effect on mineral coarse grain classification.

Features of Spiral Classifier

1. High-quality material: The body of the classifier is welded by steel plate. The inlet of the screw shaft, the shaft head and the pig iron sleeve are wear-resistant and durable. The lifting device is divided into electric and manual.

2. Easy operation: the classifier uses frequency conversion control technology, and the operation is more concise.

3. Strong wear resistance: the use of tile lining, low maintenance rate; the base is made of channel steel, and the body is welded with steel plate, good quality and high wear resistance.

4. Energy saving and high efficiency: low energy consumption, high efficiency, and high precision.

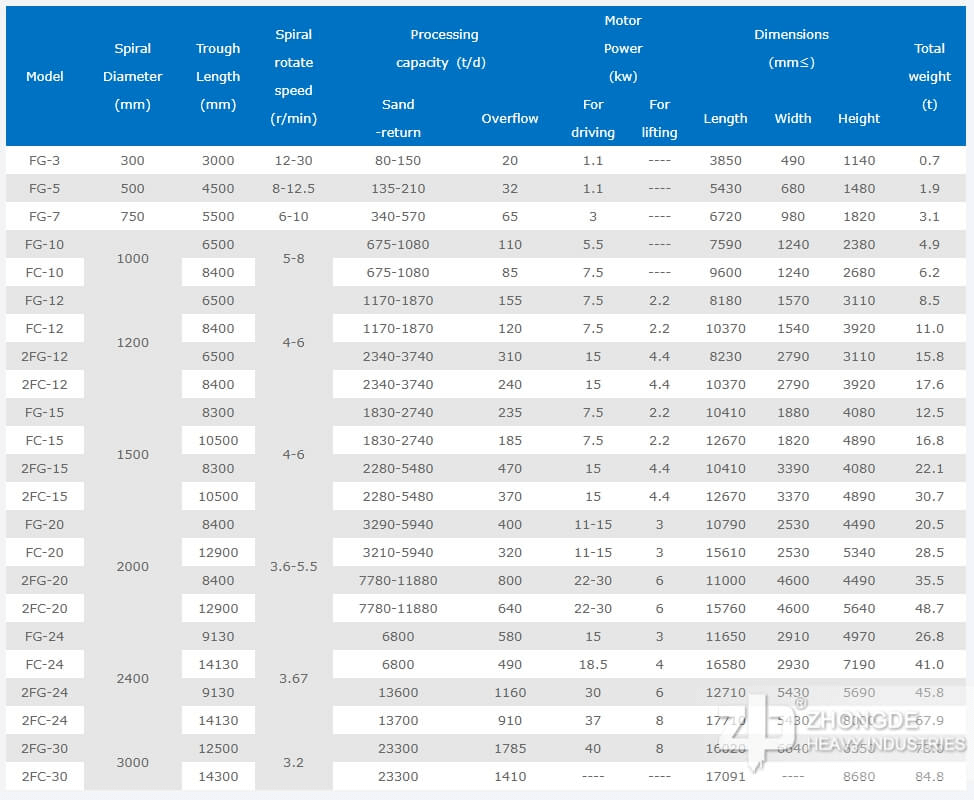

Technical Data of Spiral Classifier

Under different specifications spiral classifier corresponding classification requirements, such as electrical power, the size of the venue and the production aspect and other forces are unequal, so it is recommended that the user purchase machine according to actual production requirements.

Above models of Zhongde's spiral classifier is available. In addition, for some users with special requirements, Zhongde also supports customized design and manufacture, and the delivery cycle is short, which does not delay the normal operation of the user.

Technical Data Description of Spiral Classifier

For the spiral classifier with model specification 2FG-12, 2 indicates that the model is a double spiral classifier, single screw has no digital description; F is the abbreviation code of the spiral classifier; G indicates that the model is a high-end spiral classifier. machine, and C is represented as a sinking spiral classifier, and the number 12 means spiral classifier with the specifications for the coil diameter of 1200mm.

Key Points of Spiral Classifier

Spiral classifier screw shaft is important to ensure normal operation of equipment components, so customers are more concerned about the screw shaft wear. A good quality of the screw shaft is made of extra-thick seamless steel pipe, and the defective product is welded. High-intensity and overload operation also wears the screw shaft and shortens the service life. The screw shaft will be worn or even broken because of improper operation and maintenance, so the maintenance of the machine will be emphasized.

Price of Spiral Classifier

1. Good quality machine has long service life, so the price is higher.

2. The size of the device is large, the processing capacity is large, and the price is higher.

Manufacturer & Supplier

Henan Zhongde Mining Machinery Co., Ltd is a joint-stock mining machinery manufacturing enterprise integrated with scientific research, production and marketing. With an area of 50 thousand ㎡ which includes 15,000 ㎡ of standard heavy duty industrial workshop, Zhongde produces and exports powder grinding equipment, mineral processing equipment, dryer machine equipment, and building materials equipment, etc. We can design the machines according to your special requirements, and we provide one-stop turnkey solutions.

Quotation and price: Zhongde is a direct-selling manufacturer, so the machines are sold at ex-factory price, lower than the market price. In order to send you a suitable machine price, we need to know machine types, capacity, processing material, input and output size, etc.

There are three quick ways to get the latest quotation.

1. Chat online

2. Leave a message on website

3. Send email to us sino@zdzg.com

Service

1. Visit the factory (free car pick-up )

2. 24-hour online service

3. Complete technical guidance

4. Free customized design

5. Free test new machine

Contact Us

Company: Henan Zhongde Mining Machinery Co., Ltd (Zhongde)

Phone: 0086-379-67399999

Email: sino@zdzg.com

Address: Luoxin Avenue, Xin'an, Luoyang, Henan, China

NOTE: please feel free to fill out the form below in detail and you can also send a message to us(sino@zdzg.com), we will send you latest price within 24 hours.Besides, you can click Chat Online on the right hand side to get quotation online