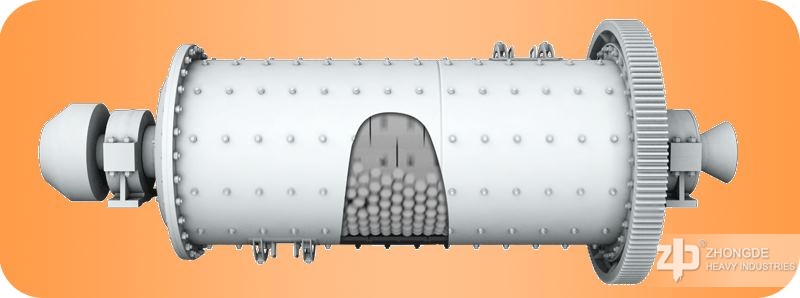

Cement ball mill is the key equipment for grinding fine powder mainly used in cement industry. It also can grind many kinds of ores like iron ore, slag, copper ore, gold ore in ore beneficiation plant.

Cement Ball Mill

4 factors that affect the capacity of cement ball mill

1.Feeding size of cement

The smaller the particle size of cement material, the higher the output and efficiency of the cement ball mill, contrarily, the cement ball mill has lower yield and higher running cost.

2.Moisture of cement

Cement ball mill grinds cement by dry grinding. If cement material has more moisture, there will be easier to lead to blockage of ball mill machine.

3.Grinding process of cement ball mill

The whole grinding system has great influence on the grinding efficiency. Compared with open-circuit process, cement material can be processed effectively in the closed-circuit process.

4.Fineness of finished product

Just like feeding size of cement raw material, the finer the output material, the lower the capacity of the ball mill; the coarser the finished product, the higher the capacity.

Ball Mill Principle

4 ways to increase the capacity of cement ball mill

1.Using cement crusher to reduce cement size

2.Using separator to select raw material with different particle size

3.Using drying machine to decrease the water content of cement

4.Improving ball mill grinding system

Visit Zhongde Factory

NOTE: please feel free to fill out the form below in detail and you can also send a message to us(sino@zdzg.com), we will send you latest price within 24 hours.Besides, you can click Chat Online on the right hand side to get quotation online