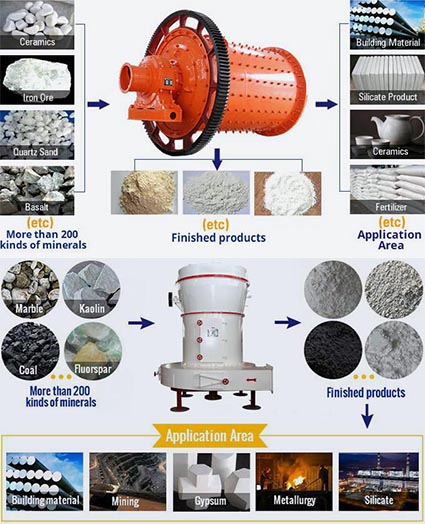

Application Field

Ball mills are mainly used in grinding operations in the fields of ore processing plants, cement construction, silicate products, new building materials, refractory materials, glass ceramics and black and non-ferrous metal beneficiation. Raymond mill is used for materials with Mohs hardness not more than 9.3 and a humidity below 6% like calcite, potassium feldspar, talc, barite, marble, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass, insulation materials, etc. in non-flammable and explosive minerals, chemicals, construction and other industries. By Raymond mill, more than 280 kinds of materials can be processed into high-fine flour. Raymond mills can only be used for grinding non-metallic work.

Grinding Methods

Ball mills have grinding methods-dry grinding and wet grinding. The wet ball mill is used to grind the material with water or a material containing a certain amount of water. The dry ball mill does not allow the material to be ground with water. Raymond mills can only perform dry grinding operations.

Technical Parameter

The ball mill feeding size is ≤20-≤25mm, the output size is 0.074-0.89mm (30-300 mesh), and the capacity is 0.65-615t/h according to the specific production situation of the user. Raymond mill has a feeding size of ≤30mm, a production fineness of 100-500 mesh (0.044-0.173mm), and capacity can be used up to 16-176t/h according to the fineness of different materials. The ball mill is more suitable for coarse grinding of materials, and the Raymond mill is more suitable for fine grinding of materials.

Working Principle

In the operation of the ball mill, it mainly relies on the impact grinding and stripping operation of the grinding medium steel ball and the material to achieve the crushing of the material. During the Raymond grinding operation, the grinding roller and the grinding ring roll compact the material under the action of centrifugal force during the rotation of the device to achieve the purpose of material grinding.

Price & Quotation

Three quick ways to get the latest quote

1. Consult online customer service

2. Leave a message online

3. Send email to us sino@zdzg.com

(Direct-selling manufacturer, ex-factory price, lower than the market price. In order to send you a suitable machine price, we need to know machine types, capacity, processing material, input and output size, etc.)

Service

1. 24-hour online service

2. Full tech support

3. Customized design

4. Maintenance and Repair

Company

Henan Zhongde Mining Machinery Co., Ltd is a joint-stock mining machinery manufacturing enterprise integrated with scientific research, production and marketing. With an area of 50 thousand ㎡ which includes 15,000 ㎡ of standard heavy duty industrial workshop, Zhongde produces and exports powder grinding equipment, mineral processing equipment, dryer machine equipment, and building materials equipment, etc. We can design the machines according to your special requirements, and we provide one-stop turnkey solutions.

Welcome to Visit the Factory

Company Name: Henan Zhongde Mining Machinery Co., Ltd (Zhongde)

Phone: 0086-379-67399999

Email: sino@zdzg.com

Address: Luoxin Avenue, Xin'an, Luoyang, Henan, China.

NOTE: please feel free to fill out the form below in detail and you can also send a message to us(sino@zdzg.com), we will send you latest price within 24 hours.Besides, you can click Chat Online on the right hand side to get quotation online