Feeding Size:≤25mm

Finished Product Fineness: 400-800 mesh

Application Area: calcium carbonate pulverization processing, gypsum powder processing, power plant desulfurization, non-metallic mineral milling, pulverized coal preparation, etc.

Free Inquiry

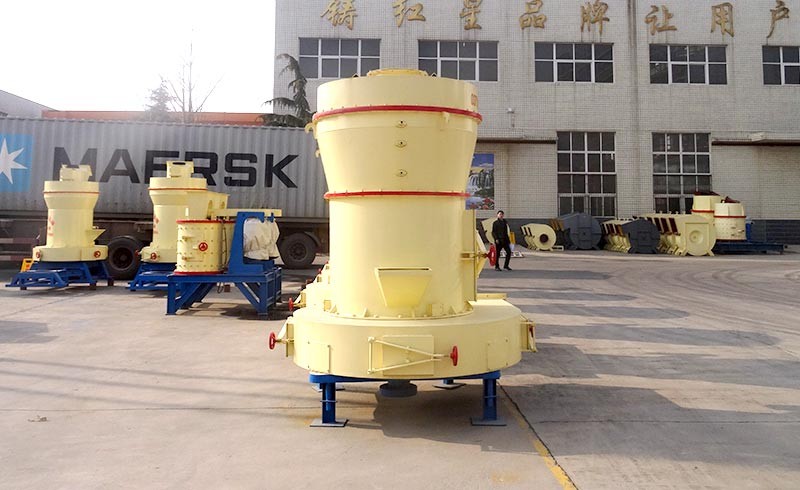

Free Inquiry High-strength pulverizer is referred to as high-strength mill, which is a new type of mill introduced by Henan Zhongde Mining Machinery Co., Ltd. This large-scale mill is especially suitable for desulfurization of large thermal power plants and desulfurization of steel plants. At present, the following models are widely used in the market: 93, 95, 96, 86, 83, etc.

High-strength grinding mill can be used in non-flammable and explosive mines, metallurgy, chemicals, building materials and other industries. It is suitable for crushing materials such as barite, limestone, ceramics and slag with a Mohs hardness of not more than 9.3 and a humidity of 6% or less. The finished grain size is adjusted in the range of 80-425 mesh (the finest 1000 mesh). A 30-80 mesh coarse powder can be produced by adding special equipment inside the machine.

Outstanding Advantages:Uniform fineness, high screening rate, stable transmission, reliable operation and high wear resistance

Principle of Operation:In the high-strength grinding machine, a high-pressure spring with a pressure of 1000-1500 kg is fastened on the roller hanger. After starting work, the grinding roller rotates around the main shaft and rolls against the grinding ring under the action of the high-pressure spring and the centrifugal force. The pressure is 1.2 times higher than that of the Raymond mill under the same dynamic conditions, so the output is greatly improved. When the material to be ground enters the grinding chamber, it is shoveled by a blade and fed between the grinding roller and the grinding ring for rolling. After rolling, the powder is brought into the analyzer along with the circulating air of the blower. The qualified fine powder enters the cyclone powder collector as the finished product, and the large granular material falls back to be reground.

The circulating air is returned to the blower and the above process is repeated, and the residual air is purified by the bag filter. When the wear of the grinding roller and the grinding ring reaches a certain level, the length of the high-pressure spring should be adjusted to maintain a constant rolling pressure between the grinding roller and the grinding ring, thereby ensuring stable production.

HTTP Status 400 – Bad Request

NOTE: please feel free to fill out the form below in detail and you can also send a message to us(sino@zdzg.com), we will send you latest price within 24 hours.Besides, you can click Chat Online on the right hand side to get quotation online